Aluminum Laptops: Advantages and Disadvantages

Aluminum laptops have gained popularity in recent years, especially in the premium segment. The main reason for this preference lies in the advantages offered by this material. However, it also presents some drawbacks that are important to consider. This article will explore the key features of aluminum laptops, as well as the differences between construction types and their impact on durability.

Advantages of Aluminum

Strength and durability: Aluminum is known for its sturdiness and ability to withstand mechanical stress, making it an ideal material to protect the internal components of a computer.

Attractive design: Aluminum devices often have a sleek and minimalist finish, making them especially appealing to users who value aesthetics and functionality.

Lightweight: Despite its strength, aluminum is relatively light, contributing to the portability of the device.

Corrosion resistance: Unlike other metal materials, aluminum is highly resistant to oxidation, ensuring a longer lifespan in humid environments.

Thermal Conductivity Issues

One of the main drawbacks of aluminum is its high thermal conductivity. Depending on the device's design, the heat generated by internal components can be transferred to the surface of the chassis. This may result in an uncomfortable user experience, especially during long sessions or when performing high-performance tasks.

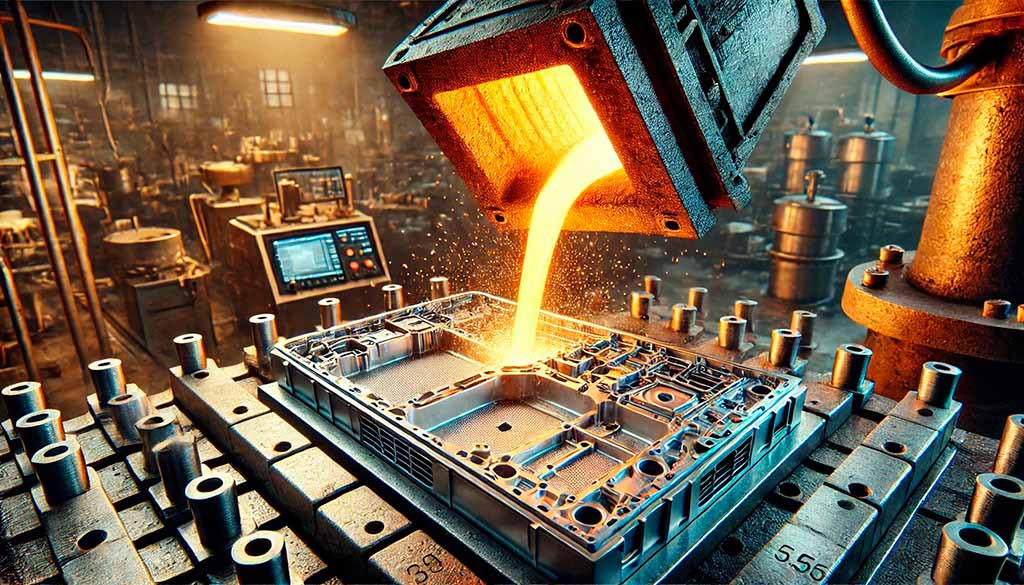

Types of Aluminum Laptops

There are two main approaches to building laptops with aluminum chassis:

Fully aluminum construction: In laptops like Apple MacBooks, the entire chassis is made of aluminum, with hinges and internal components screwed directly into it. This ensures a solid structure and precise assembly of parts.

Aluminum chassis with plastic substructure: Some manufacturers use a design where the outer shell is aluminum, but the internal components and hinges are attached to a plastic subframe glued to the casing. This approach can reduce the device’s overall durability and rigidity, potentially making it less durable than a laptop built entirely from aluminum—or even plastic. This type of design is generally more affordable compared to models fully made of aluminum.

Fragility to Impacts

Although aluminum is robust, it has a major downside: it tends to dent easily if dropped or hit. This can affect both the aesthetics and functionality of the device. In this regard, plastic can offer better impact resistance, as it is more flexible and absorbs deformation more effectively without leaving visible marks.

Durability

In models made of plastic or with plastic subframes, the screw threads are inserted directly into the plastic, which requires several precautions to maximize durability:

- Maintenance: Stiff hinges can lead to breakage. Over time, it’s important to properly adjust and lubricate the hinges. If you notice excessive stiffness, creaking, or twisting of the case, maintenance should be performed.

- Responsible use: Applying too much force when opening the screen beyond its limit or closing it too forcefully can damage the casing over time. Always open and close the screen gently and preferably from the center.

- Other uncontrollable factors: Aspects such as the manufacturer's design or the intensity of use can result in some models being less durable.

These issues rarely affect laptops built entirely from aluminum, as their solid construction and structural strength minimize the risk of damage to internal fastenings.

Conclusions

Aluminum laptops offer a combination of durability, sleek design, and portability, making them ideal for demanding users. However, it is essential to consider their limitations, such as heat transfer and susceptibility to dents. Ultimately, the choice between a fully aluminum model or one with a plastic subframe depends on the user's priorities regarding durability and budget.